Meet the HP Jet Fusion 3D 4200/3200 Printing Solution

Reinvent how you prototype and produce functional parts, delivering quality output, up to 10 times faster at half the cost.

Breakthrough speed

Breakthrough speed up to 10 times faster with 30 million drops per second across each inch of the working area

Extreme accuracy and fine detail

HP fusing and detailing agents work with HP Multi Jet Fusion technology and materials to deliver fine details and dimensional accuracy

Voxel-level control

Accurate thermal control of every layer enables predictive corrections voxel by voxel for optimal mechanical properties

Maximum control during progress

In-printer quality checks reported via a touchscreen, help minimize errors and enable easy and accurate job progress tracking

Reduce labor time

Automated material mixing and loading systems help streamline your workflow and reduce labor time

Cleaner experience

No additional room for parts removal needed with enclosed unpacking and material collection system, including a laminar hood

More parts per day

The HP Jet Fusion 3D Fast Cooling Module reduces cooling time resulting in faster time-to-part and more parts ready within the same day

Maximize productivity

The HP Jet Fusion 3D Build Unit— included within the printer— is moved on for cooling right after job completion allowing a continuous printing process that maximizes productivity

Maximum efficiency

Optimize cost and part quality, with cost-efficient materials that offer industry-leading reusability. Plan production times more accurately and predictably, to increase your overall operational efficiency.

Reduce labor time

Automated material mixing and loading systems help streamline your workflow and reduce labor time

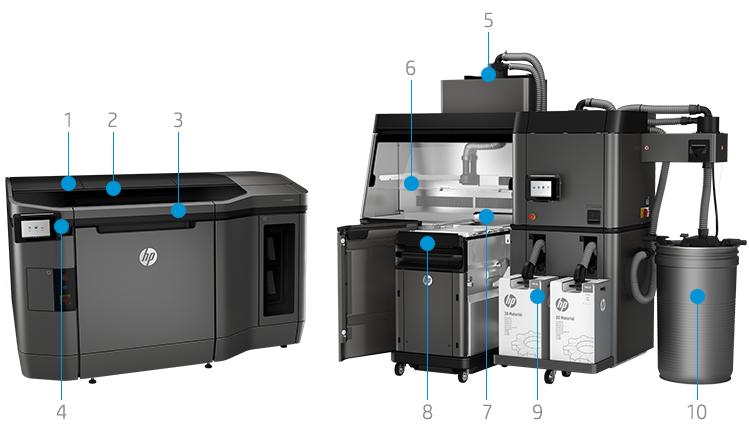

1. Breakthrough speed

Breakthrough speed up to 10 times faster with 30 million drops per second across each inch of the working area

2. Extreme accuracy and fine detail

HP fusing and detailing agents work with HP Multi Jet Fusion technology and materials to deliver fine details and dimensional accuracy

3. Voxel-level control

Accurate thermal control of every layer enables predictive corrections voxel by voxel for optimal mechanical properties

4. Maximum control during progress

In-printer quality checks reported via a touchscreen, help minimize errors and enable easy and accurate job progress tracking

5. Reduce labor time

Automated material mixing and loading systems help streamline your workflow and reduce labor time

6. Cleaner experience

No additional room for parts removal needed with enclosed unpacking and material collection system, including a laminar hood

7. More parts per day

The HP Jet Fusion 3D Fast Cooling Module reduces cooling time resulting in faster time-to-part and more parts ready within the same day

8. Maximize productivity

The HP Jet Fusion 3D Build Unit— included within the printer— is moved on for cooling right after job completion allowing a continuous printing process that maximizes productivity

9. Maximum efficiency

Optimize cost and part quality, with cost-efficient materials that offer industry-leading reusability. Plan production times more accurately and predictably, to increase your overall operational efficiency.

10. Flexibility

Print using different materials.

The HP Jet Fusion 3D External Tank allows the extraction of recycled material from the Processing Station so it can be replaced by a different material.

HP Jet Fusion 3D 4200 Printing Solution

Ideal for your prototyping and short-run manufacturing needs, with high productivity1 to meet same-business-day demands, at lowest cost per part

- Experience enhanced performance thanks to a higher disk capacity and additional memory

- Achieve an even lower cost per part versus the HP Jet Fusion 3D 3200 printing solution

- Use advanced and custom print modes to control mechanical, functional, and aesthetic properties, accuracy, and speed

- Benefit from advanced part quality monitoring during printing

- Add additional parts – while printing is already in progress – for urgent jobs

HP Jet Fusion 3D 3200 Printing Solution

Ideal for prototyping, giving you improved productivity1 and the capacity to grow your usage at a low cost per part

See the complete HP 3D Printing workflow

HP 3D Software—Maximum 3D printing efficiency

Complete, easy to use solutions that deliver quality parts and breakthrough productivity.

Job preparation and monitoring

HP SmartStream 3D Build Manager

All you need to start your 3D printing project—intuitive and powerful software with the essential features to prepare and send your parts to print.

HP SmartStream 3D Command Center

Fully monitor your HP Jet Fusion 3D Printers from your desktop. Keep track of build status, check consumables, and get real-time alerts.

Integration with industry-leading solutions

Autodesk® Netfabb® with HP Engine

Provides advanced software for the additive manufacturing of production quality parts. Quality control functions prevent machine errors and enhance your overall process reliability and efficiency.

Materialise Build Processor for HP Multi Jet Fusion

Connect with Materialise Magics with Materialise Build Processor for HP Multi Jet Fusion, the industry standard software for professional 3D Printing, to unlock the full potential of your HP 3D printer and manage every step in your production process.

Founding member of 3MF Consortium

HP is a founding member of the 3MF Consortium—an industry consortium working to define a new 3D printing format that will allow design applications to send full-fidelity 3D models to a mix of other applications, platforms, services and printers.